During spring and summer 2019, as crews excavated for the foundation of the new Bonney Science Center, they removed a stunning amount of ancient blue-gray marine clay — more than 10,000 cubic yards, according to an estimate from subcontractor Gendron & Gendron.

We watched captivated as excavating machines scooped and scraped the clay, all clingy, sculptural, and glistening like unappetizing Jell-O. For weeks on end, a procession of G&G dump trucks arrived empty at the Campus Avenue site, across from Carnegie Science, and drove away full of clay.

We found it remarkable, but for G&G, as for earthwork contractors in much of Maine, it was no big whoop.

Likewise unsurprising to the construction team was the behavior of the clay left behind in the ground, which complicated preparations for laying the science center’s foundation — in what was just another installment of the complications clay has caused for the people who build and maintain facilities at Bates.

Still, in an ode to the transformative power of a 2,000-degree kiln, clay will soon find redemption at Bates. When it’s time to start covering the science center’s concrete walls, the college will look to Morin Brick Co., which will make the bricks for the job from its very own clay, mined across the river in Auburn.

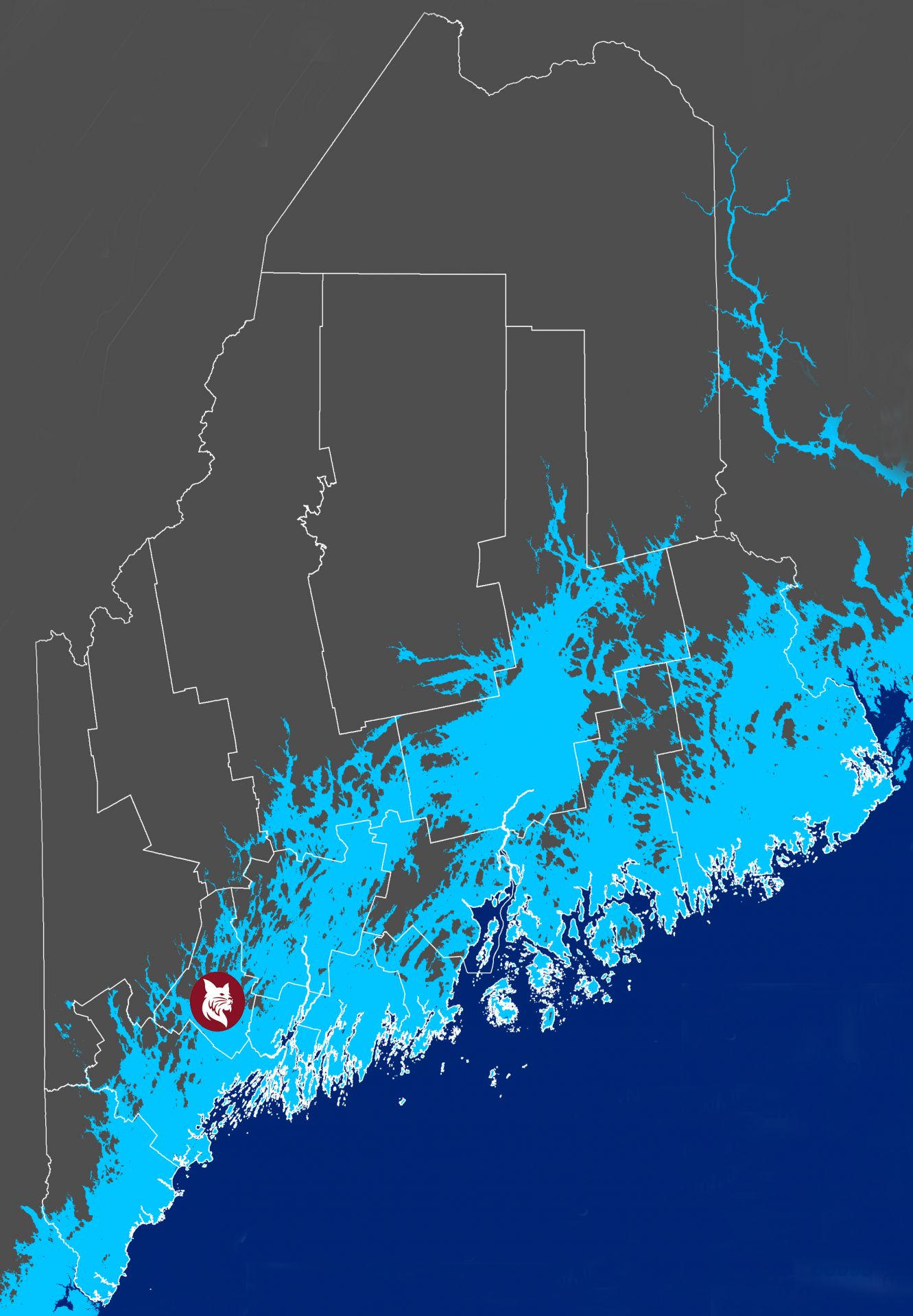

The Morin mine and the Bonney site are parts of the glaciomarine clay layer that geologists call the Presumpscot Formation. Thousands of years old, the formation extends from Maine’s coast well inland, as far north as Millinocket.

(The formation was named in 1959 by a Yale doctoral student. Hurrying to finish his geology dissertation, he chose the clay-banked Presumpscot River, in southern Maine, for the formation’s namesake after his first choice, “Portland,” was rejected by his professors as being overused.)

Along with Maine’s many ponds and its rounded-off mountains, the Presumpscot Formation is a product of the Pleistocene Ice Age. About 35,000 years ago, according to the Maine Geological Survey, the Laurentide ice sheet began expanding into New England. At its largest, the sheet covered all of Canada and parts of the U.S. It grew thick enough to conceal Maine’s highest mountain, Katahdin, which stands nearly a mile above sea level.

So how does a glacier make clay? Friction is part of the answer. As the ice sheet advanced and retreated over time, it ground up and carried away whatever got in its path, even bedrock, which included feldspars, micas, and quartz. The smallest bedrock particles were fated to become clay. (The U.S. Geological Survey categorizes as clay those particles smaller than .002 millimeters, which are too small to see without a strong microscope.)

And the other clay-making thing the glacier did was melt. In our region, the ice sheet reached its maximum extension near today’s Georges Bank fishing ground about 20,000 years ago. Then, as the climate warmed, the retreat began, a slo-o-o-w melting back over thousands of years.

Glacial meltwater washed away the rock particles the ice had picked up during its advance. Over the centuries, these and other detritus liberated from the ice sheet flowed into the sea and settled on the seafloor — which was far inland from the present coastline. That’s because the unimaginable weight of the glacier, in a process called isostatic depression, smushed the land beneath it down to levels that were hundreds of feet well below current elevations.

Around 14,000 years ago, explains Bates geologist Mike Retelle, the meltwater was entering the sea at a delta at the south end of today’s Lake Auburn. (Retelle and UMaine geologist Thomas Weddle co-edited a book on Maine’s postglacial history.)

“Gracelawn Cemetery is the top of that delta, so if you’d been able to stand on the shoreline there, you’d be looking at kind of a fiord environment,” with water surrounded by sharply higher land, Retelle explains.

Much of the region otherwise was submerged, including the low-lying portions of Bates — that is, virtually all of campus — and the neighborhood. At the sea’s highest stand, Retelle estimates, the Bonney site was under 100 feet of seawater. And all the while, sand, silt, and clay were washing in with the meltwater and settling right where Bates and other institutions would later want to build things. (The nerve!)

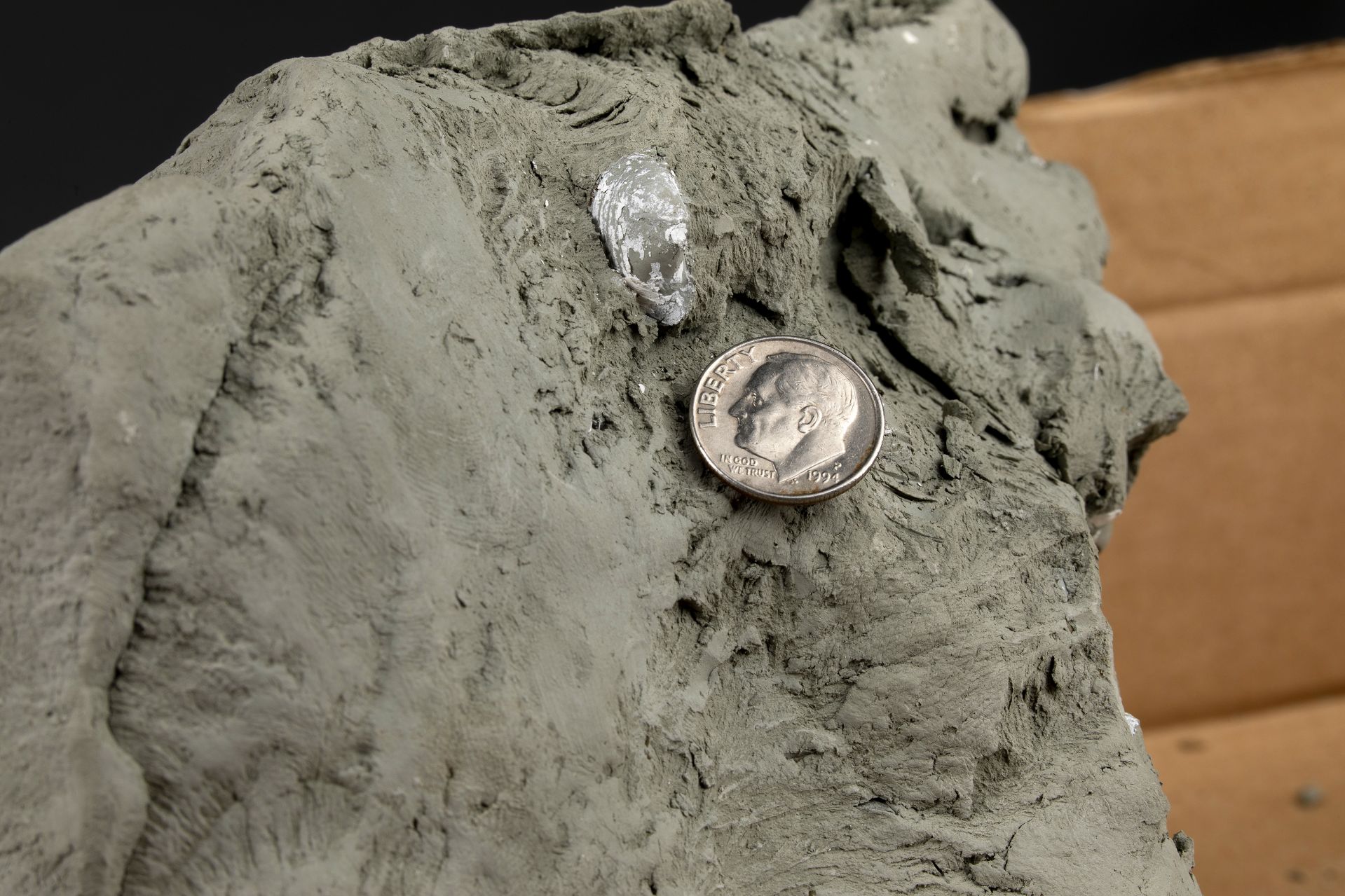

One indication that Presumpscot Formation clay is sited on an ancient seabed, as opposed to some lake bottom, is the presence of preserved sea animals, including marine mollusk shells from the genus Yoldia, specimens of which turned up at the Bonney site during a June visit by Retelle, Beverly Johnson, and other geology faculty (a shell will be carbon-dated). In Augusta, the Maine State Museum has remains of a walrus and a mammoth found elsewhere in Maine clay.

The dynamics of this whole business get confusing. Being depressed in an isostatic sort of way, the land surface was much lower during the glacier’s reign — but so was sea level, because so much water was captive in glaciers around the world. As that water was released, sea levels rose. But so did land elevations — rebounding as the weight of the ice sheet went away. Today, the science center site is about 250 feet above sea level.

Maine has a longstanding love-hate relationship with Presumpscot Formation clay. In the “I Love PF Clay” column, Maine ceramicists make plates and pots from it. In addition, its cohesiveness makes it useful for capping defunct landfills. (And for water retention in Lake Andrews, whose floor, beneath the duck deposits, is marine clay.)

Of course, as mentioned above and below, Maine clay generally makes good bricks. (Morin adds a bit of sand to stabilize its formula.) In the 19th century, brickyards abounded in Maine. According to the Bangor Daily News, the town of Brewer alone had 18 brickyards in the 1870s.

And the “Hate” column? While Presumpscot clay goes into bricks that are good to build with, it’s not so swell as a substance to build upon. Compressed by the weight of a building, highway overpass pier, etc., a clay layer is prone to settling, and unpredictably so. While adding a frisson of adventure to your building project, these qualities often necessitate time-consuming and expensive “soil improvements.”

Prior to the construction of Lane Hall, in 1963, President Charles Franklin Phillips reported to the trustees that “[W]e swallowed hard when informed that the earth formation on the proposed site is such that 144 piles” were needed to support the building’s foundation. Phillips doesn’t say “clay,” but we’re thinking he meant clay.

During site preparation for Kalperis Hall, a couple blocks down the clay deposit from Bonney Science, an initial round of injected soil reinforcements, each resembling a stack of doughnuts, proved inadequate. A second round used a different approach, known as GeoConcrete Columns, which created underground piers with a bulbous, onion-shaped base.

Bonney Science itself, being constructed on clay that’s 50 feet or so thick (thicknesses of 200 feet have been documented in the Presumpscot Formation) required more than 200 so-called pipe piles to stabilize the soil.

“Without that layer of clay, we likely wouldn’t have needed to drive piles,” says Chris Streifel, the Facility Services project manager overseeing the Bonney and previously the Kalperis–Chu Hall projects. “It’s definitely made life more challenging. It’s mucky, messy, and slippery. It’s not a fun substance to work with in general, but that’s the nature of the business.”

Clay is the font of other dubious blessings. It makes a poor bed for parking lots, steam vaults, etc., which necessitates replacing it with more stable soils as part of infrastructure makeovers. Plants don’t thrive in clay, so grounds crews planting a tree or shrub in a new spot will generally “want to put in some good organics and soil in place of clay to get things to root,” says Jay Phillips, director of Facility Services operations.

Then there’s drainage (not). Spring rain and snowmelt can collect in long-lasting puddles on campus that are big enough for the ducks to enjoy. Garcelon Field was infamously damp and mucky until drainage infrastructure was installed, in 1986. “Only the muddy condition of the field, which made it impossible to kick a goal from a touchdown, gave the victory” to the University of Maine, The Bates Student griped after a 7-6 Bobcats loss in 1912.

But once water permeates clay, the clay wants to keep it. So Presumpscot Formation clay tends to be wet. Wet clay is plastic (hence the instability) and it’s also, weirdly, both slippery and sticky, depending on which condition will cause the most inconvenience, especially to the people who work closely with it on a job site every day. A Google search on “removing clay from clothes” generated 35,500,000 results.

A smaller but more meaningful number is the estimated count of brick — brick professionals don’t pluralize with “s” — needed to sheathe the walls of the Bonney Science Center: 180,000, project manager Streifel estimates.

The clay for those bricks (sorry, we need the “s”) is coming out of a mine in a field near a stand of trees in Auburn’s Danville neighborhood. And not far from the field is the Morin Brick Company plant.

On a July morning we met Morin’s director of sales and marketing, Jason Lachance, whose family once owned the company and who started in the brickyard when he was 17. Our visit included a drive past the lot where freshly mined clay is rototilled, dried, and stored in heaps; and a distant look at the mine itself.

We couldn’t get close because the dirt road was paved with rejected bricks that keep heavy machinery from bogging down but are too jagged for passenger vehicles.

Two employees of Shaw Brothers Construction, an earthworks contractor in Gorham, Maine, work the open-pit clay mine for Morin. “It’s about 86 acres,” Lachance said. “We’ve been mining there now for approaching 30 years,” with perhaps another five to 10 years of life left in the deposit. Given the need to find clay matching its established processes and customer interests, Morin is already taking steps to secure its next clay source. (The National Brick Research Center, at Clemson University, assays prospective clays for Morin.)

Founded in 1912 and now Maine’s last maker of clay brick, Morin also bills itself as North America’s last manufacturer of “waterstruck” brick. Where most brick is extruded, like dough from a pasta machine, waterstruck is made with the age-old technique of pressing soft wet clay into wooden molds. (“Waterstruck” refers specifically to the use of a jet of water to knock bricks out of the molds. Morin makes extruded as well as waterstruck.)

The many Bates buildings cloaked in Morin waterstruck include the 2008 Commons and, on Campus Avenue, Chu and Kalperis halls, for which the company devised an extra-long brick.

“No two waterstruck brick are exactly alike,” Lachance explained. “That irregularity and random event, if you will, combined with a manipulation of flash in the kiln” — extra-hot flare-ups — “yield some wonderful ranges of colors. The Bates campus is a perfect example of what can be accomplished with waterstruck brick.”

Not to mention what can be accomplished with waterlogged clay.