“Summertime

Demolition ain’t easy

Hammers thumpin’

And the sawin’ is nigh”

All right, so the search will go on for Campus Construction Update’s summer theme song (and our apologies go out to fans of DuBose Heyward and George and Ira Gershwin).

Nevertheless, summer remains peak season for construction at Bates, thanks to (mostly) agreeable weather and a smaller campus population. So here’s a roundup of summer 2022 construction news, including:

- a major renovation nearing completion, that being Dana Hall’s;

- a major renovation in its early days, at Chase Hall;

- refurbishment of a key athletics facility, the Russell Street Track; and more.

True to their code: If all goes according to plan, Lewiston city officials will inspect Dana Hall on June 20 as a prerequisite to issuing to Bates a certificate of occupancy.

A major milestone en route to the late summer reopening of Dana after an in-depth renovation, the inspection and certification are a process “that we’re always anxious about and hopeful it will go smoothly,” says Chris Streifel, Bates project manager for the Dana project. “There’s a lot to it.”

The inspection will emphasize conditions relating to life safety, accessibility, and compliance with building codes — things like functioning doors and elevator, unobstructed egresses and walkways, operational lighting, sanitation, and ventilation systems, and so on.

“We need to have primary finishes completed as well,” Streifel adds. “There can’t be rough construction still to do. So flooring should be down and walls painted.”

Michael Carpentier is the Dana project superintendent for Consigli Construction, the firm managing the project for Bates, and he will accompany the city building inspector and fire department officials during their visit.

Streifel says, “I’m confident that we’re going to be where we need to be” in terms of renovation progress by the 20th. “There’s a lot left to do, there’s no doubt about it. But there isn’t anything that appears to be throwing us off that objective. It’s a reasonable objective.”

Another milestone will likely appear soon after the occupancy certificate is issued: a formal declaration of substantial completion, which “could come as little as a week later,” says Streifel.

Substantial completion means that a project has met the objectives stipulated in the contract between construction manager and client. And it means that the legal ownership of the building in question reverts from the construction manager to its nominal owner — that being Bates.

Next, the college will spend a couple weeks moving furniture and supplies into the 57-year-old Dana, a former chemistry facility now repurposed for introductory science education. The renovation will also serve to expand the college’s roster of general-purpose classrooms.

After a busy July getting the building squared away, Dana staff will occupy their offices starting Aug. 8. And a few weeks later Dana will reopen for classes along with the rest of campus.

Previously: Enough of looking to the future, as Campus Construction Update relapses into our preferred mindset of dwelling on (or in) the past — Dana’s recent past, at any rate. Since mid-May, various building systems have been test-started: the main air handler, HVAC water chillers, some of the variable frequency drives that operate pumps and fans for local temperature control. And Dana has been looped into the campus-wide steam system, which will heat water that heats interior air.

At the same time, Streifel says, the formal systems-testing protocol known as commissioning is in progress, albeit in an early phase that entails compiling documentation and ensuring that all the gizmos, contraptions, and whatchamacallits are properly placed and connected.

Thus far, “the commissioning agent’s been involved,” Streifel says. “We’ve had several commissioning meetings so far. But the real nitty-gritty is still to come,” that being the actual shaking-down of systems ranging from HVAC to data to building controls. “Late June and all of July will be heavy in commissioning” (and to account for changing seasons, some commissioning will likely go on well past July).

Similarly, though punch-listing has been in progress for weeks, it will soon expand from above-ceiling mechanical and electrical fixtures to, well, everything that’s ready for inspection.

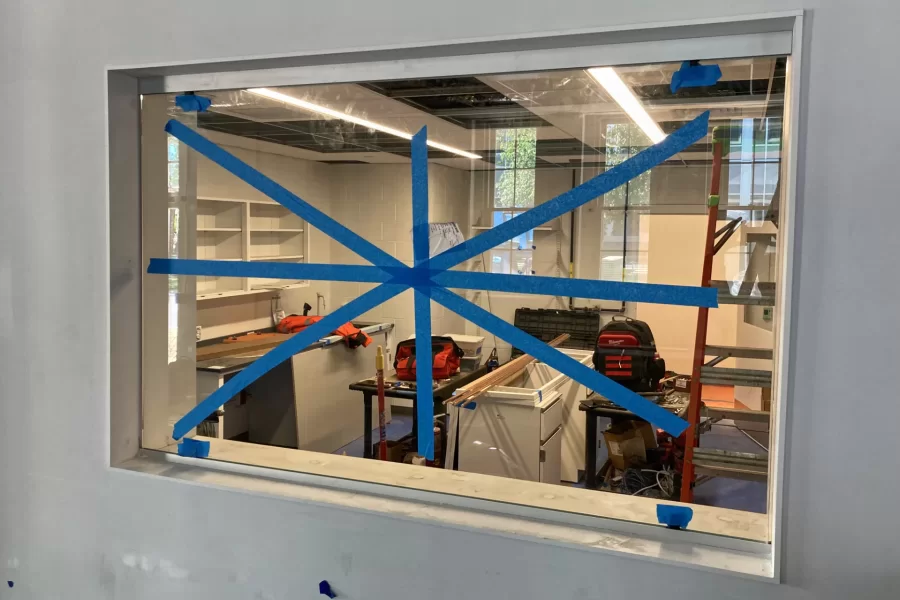

Among the three teaching floors, the first remains closest to completion. Most of the casework — lab benches, cabinets, etc. — is in place in the laboratories. Flooring is about done, ceiling grids and many tiles are in place, top coats of paint abound, a lot of glass is mounted, and some doors are hung.

“I’d say the third floor looks the least finished,” says Streifel. “But even wandering through the second floor, we’re getting to the point where we’re seeing, ‘Oh, there’s one thing left to do there, one thing left to do there, one thing left to do there’ — but we can see the end result.”

Next step: no steps: Just a couple of weeks after the view-blocking fence was removed from the Dana Hall construction site, the same kind of fence (or even the same fence!) has been erected elsewhere for Campus Construction Update to peep over.

The new barrier encloses Chase Hall, and it came along as an ambitious revamp of the century-old building has shifted to a higher gear. As we reported in March, the goal of the 15-month makeover is to bolster Chase’s original role as a student center — and the means to that end include dramatic improvements to building accessibility and wayfinding, the enhancement of student-bookable spaces, and the clustering of key Student Affairs offices.

We arrived at Chase on Monday morning just in time to watch an excavator-mounted jackhammer obliterate the stairs at the main Campus Avenue entrance. (This was the first step, no pun intended, toward rebuilding the entrance at ground level.) It gave us a pang to watch the concrete crumble, as those stairs had always seemed like a special Bates place: students waiting for the intercity bus or the Bobcat Express shuttle, folks with Chase business passing in and out, yours truly eating M&M Peanuts and staring at new construction across the avenue.

Inside Chase on Monday, an Acadia Contractors team was nearly done with a monthlong process of asbestos abatement on what the project team is calling the second floor. (Chase has something like nine levels, so we’ll just roll with it.)

Soon that team will move down one story, tape up their protective plastic sheets, and resume asbestos removal, primarily from areas of plaster-lath ceiling where new utility runs will go. They’ll concentrate on what used to be first-floor lobby and office space — you’ve probably been there — adjacent to that main Campus Avenue entrance.

Meanwhile, upstairs where Acadia had just finished, workers for PBC Environmental of Kittery, Maine, will demolish walls and eventually a section of floor. Formerly the location of offices for Residence Life and other staff, this area will become the upper terminus of a new master stairway.

Soon thereafter, explains Bates project manager Kristi Mynhier, “we’ll mobilize the framers so they can put the new wall layout in place, and the mechanical and electrical trades can come through with their rough-ins.”

Rather than executing the interior demolition on a broad front, Mynhier adds, PBC will take it one section at a time. “When you deal with structural demo, there’s always that little bit of the unknown, the need to go slow and be careful,” she says.

Track changes: After 20-plus years of service, the running surface on the Russell Street Track is being replaced this summer.

Like the previous surface, which was scraped up last month, the replacement is a product of Mondo, an Italian firm globally prominent in products for track and field facilities, among other realms. Arriving in July, the new topping is called Sportflex Super X 720.

Among related improvements to the track and field complex: the maximum depth of the steeplechase water jump has been reduced from 70 centimeters to 50, in accordance with new NCAA rules; in-ground fittings for new seasonal soccer ball-stop nets have been installed; and the complex now has a flagpole, a 30-footer erected by Lewiston’s own Neokraft Signs Inc.

The new Mondo track surface will consist of two layers. On top is Sportsflex Super X, selected for its elasticity and spike resistance — “imitated but never duplicated,” according to the manufacturer. (Just like Campus Construction Update!) The bottom layer consists of a matrix of air cells that provide athletes with nice bounce and shock absorption.

The old surface was original to the Russell Street complex, opened in 2001 as a replacement for the Garcelon Field track. The Mondo’s time was up, between exposure to the elements and simple wear and tear from all that running and jumping, as well as noontime walking by fitness-conscious Bates folks.

Miller Sports Construction of West Chester, Pa., is redoing the track for Bates. The work began in late April with the removal of the old Mondo. Under that was asphalt, and the top inch and a half, aka the wearing course was milled off next. The remaining base layer and the supporting substrate are all holding up well — as project manager Paul Farnsworth points out, a survey of the track early in this project showed that the substrate had pretty much retained the grades created during the original construction.

A new wearing course was laid this week. After 30 days of asphalt curing, more or less, it’s the Mondo’s turn (not to be confused with the soap opera As the World Turns, or the novel As the Earth Turns by Gladys Hasty Carroll, Class of 1925).

The rubbery surface comes in rolls. “It’s glued down, just like flooring,” Farnsworth explains. “So there’s a guy with a trowel that spreads the adhesive, and they roll out a section and straighten it up” or stretch it to fit the curves.

Wait a minute. One person on his knees with a hand tool spreading glue for 67,000 square feet of Mondo?

Yep. Farnsworth’s own response to this startling revelation was, “He must have a Popeye right arm.”

Then, prior to striping, the glue (to say nothing of that right arm) has to cure.

And that’s not all! Farnsworth’s workload at Bates these days is typical for a Facility Services project manager in the summer. In addition to the track, he’s also overseeing the complete replacement of the HVAC system in the Olin Arts Center. While the new system will, naturally, be more efficient than the 36-year-old machinery it replaces, driving the project is the need for better humidity and temperature control in the Bates Museum of Art, housed in Olin.

Additional energy savings will come with the addition of a so-called dry cooler, which takes advantage of cold temperatures outside to produce chilled water to help regulate temperatures inside without having to run mechanical refrigeration.

The project also entails installation of new wall insulation in the museum. During the construction, temporary climate control systems will support the museum’s stored art collection and the concert hall. The latter system is necessitated by this summer’s resumption at Bates of Gordon Research Conferences after a two-year pandemic hiatus.

Rigging the temporary HVAC in the concert hall has meant getting into ductwork above the ceiling, which in turn has meant the erection of substantial staging. “We are scrambling, working weekends, to get the work done and the staging gone before Gordon shows up,” says Farnsworth. Bates will host six Gordon research conferences this summer spanning June 25–Aug. 12.

Finally, back in the sporting sphere, Farnsworth is tending to the installation of permanent bleachers, seating up to 244, at the Campus Avenue Field. The firm A+ Athletics of Rollinsford, N.H., is doing the installation. Also in progress is the rebuilding of a pathway, newly ADA-compliant, from the corner of Central and Campus avenues to the grandstand.

Can we talk? Campus Construction Update loves to hear from you. Please send questions, comments, and reminiscences about construction at Bates College to dhubley@bates.edu, with “Campus Construction” or “Summer Construction at Bates: The Musical!” in the subject line.