Two high-profile summer projects got underway at Bates this week.

A new playing surface will be installed on Garcelon Field, replacing the FieldTurf whose arrival we told you about in 2010.

And improvements to Hathorn Hall’s third floor and attic will provide easier access to that building’s belfry, making possible, in turn, the return of Hathorn’s beloved bell to something like its old prominence.

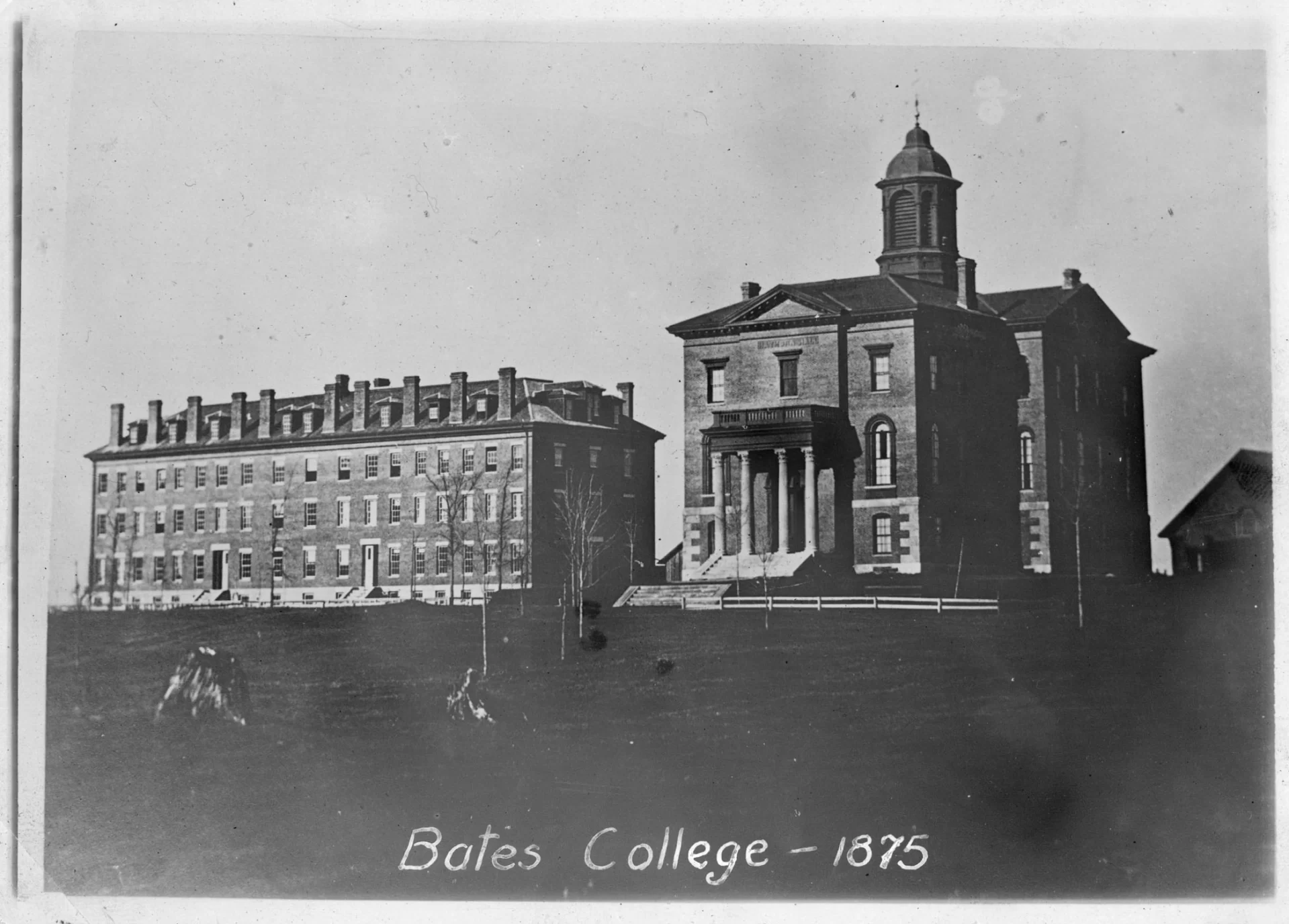

Like the work we covered last week, the ongoing renovation of Chase Hall and the creation of an immersive media studio in Coram Library, the Garcelon and Hathorn projects involve campus landmarks whose long histories resound in Bates lore.

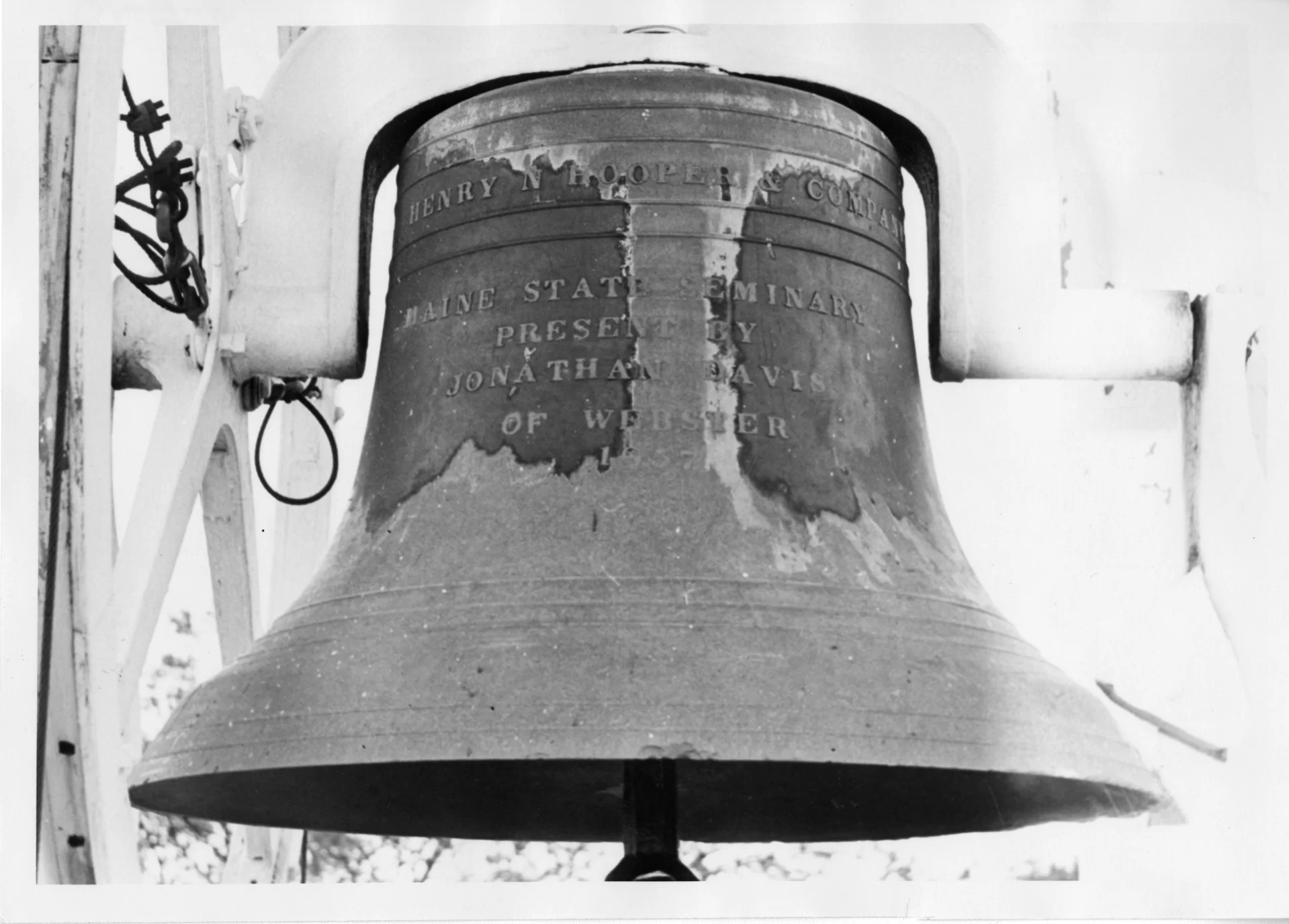

Toll house: Rung by hand some 19 times a day when it was new, in 1857, the Hathorn Hall bell has been heard from less and less in recent years.

Well into the 20th century, the 1,000-pound bell was a unifying voice on campus in ways both pragmatic and moral. The bell marked the hours of the day, summoned students to meals and chapel, and celebrated climactic moments athletic and academic, notably Commencement. Even into this century, Hathorn’s “clong” resounded at class times and the noon hour. (Until the mid-20th century, the bell was rung by students carefully selected for their reliability — not to mention their tolerance for a spartan living situation, as they resided in a room in Hathorn under less than cozy conditions.)

In recent years, though, the bell has been rung only for Commencement and Convocation. That’s because the bell’s own stock in trade — time itself — has caught up with both the bell and its structural surroundings.

The electric ringing mechanism has become unreliable and potentially hazardous. Getting into Hathorn’s attic and thence the belfry, currently via a stepladder from the third floor, takes nerve and some muscle. The attic itself is dark, grimy, and confusing — a thicket of 166-year-old beams and joists — and visitors must closely watch where they put their feet. (Note to self: submit bill for shoe lost in attic.)

A primary objective of this summer’s project is to dramatically improve not only access to the attic, via a new retractable stairway, but lighting and walkways. Also in the cards is a replacement for the ladder up to the belfry (where yet a third ladder and trapdoor provide access to the bell itself). All of that work will pave the way for replacement of the ringing mechanism.

The attic project also entails the removal of four old HVAC machines and the installation of a single state-of-the-art unit that will serve the third floor, says Brian Lanoie, Bates project manager for aspects of the work not directly related to the bell.

The present ringing system uses an electric winch to pull a cable that’s looped around the bell wheel, rocking the bell and causing the free-swinging clapper to strike the interior. (It’s not clear when the winch system was installed, though a 1956 issue of The Bates Student contains a possible allusion to that development.)

Normally the system is controlled by a timer, found elsewhere in Hathorn, that’s programmed to ring at specified dates and times. A manual override is used for special occasions such as Commencement.

While it has still been rung for special events, “the bell has not been routinely active for a couple years now” because of the need for upgrading “to a more contemporary and safer set-up,” says Alan Kelley, mechanical services manager for Facility Services.

In particular, the cable-and-winch mechanism poses a risk of dislodging the bell from its mounting. “It’s a rare event, but out of an abundance of caution, we chose to shut it down for routine operation until it can be modified.”

In the new mechanism, the bell itself will sit still and an electronically activated clapper will strike its sides. Interestingly, this marks a change in the basic technology of the Hathorn bell: No longer will rope, student muscle, cable, nor a winch be needed to evoke that familiar sound.

“Once the attic is renovated and we have safe access, the bell controls will be retrofitted and put back in regular service,” Kelley says.

A Portland company, MW Hoss, will install the new attic ladder and plywood flooring. Also on the job are two local firms, DeBlois Electric of Lewiston and Nason Mechanical Systems of Auburn. This week‘s work began with a day of site mobilization, says Brian Lanoie, and by the end of the week there should be a hole in the third-story ceiling to accommodate the removal of old HVAC equipment, and ultimately the installation of new access stairs.

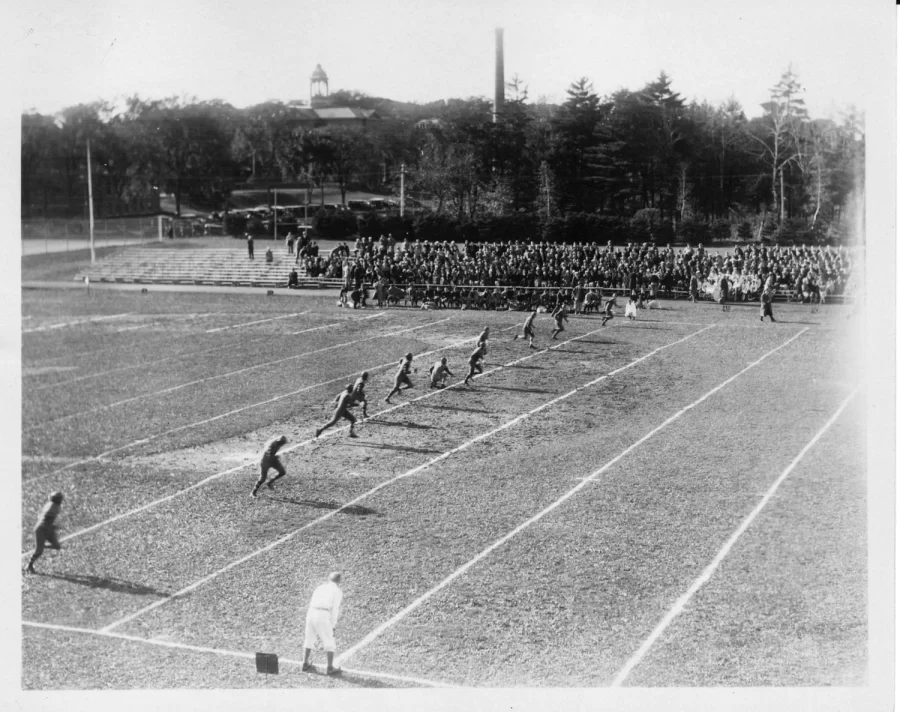

Turf’s up: Regarded as one of the 10 oldest college football fields in the U.S., Garcelon Field will renew its claim to modernity this summer with the replacement of its 13-year-old playing surface. (A marker at Garcelon, by the way, notes that Bates was the site of the first college football game in Maine. But the game itself, against Tufts, took place across campus where the Gillespie Hall dorm now stands.)

R.A.D. Sports, the Massachusetts company that installed the current FieldTurf surface in 2010, submitted the winning bid to overhaul the field again. The black chain-link fence surrounding the field will also be replaced. The work will likely be complete by early August, says Director of Capital Planning and Construction Chris Streifel, who is managing the project.

The new surface will be a Shaw Sports Turf product called Legion. Like the 2010 FieldTurf, Legion will consist of a grass-like plastic matrix buffered with a mix of sand and crumb rubber particles. Such products resemble natural grass in their playing qualities, but are much easier to maintain and more durable.

After getting established at the site, removing the old turf, naturally, is R.A.D.’s first order of business. Streifel notes that where the 2010 turf installation (which, by the way, was the first use of an artificial surface on that field) necessitated substantial underground drainage work, this summer’s effort is much simpler.

“After the existing turf is removed, the contractor will do some very fine grading to restore the precise slopes needed,” says Streifel. And then the new surface will go down. Streifel adds that the graphics on the new turf will be updated.

And what will happen to the old turf? “We may retain some of it for use in the storage areas beneath the grandstand,” Streifel says, and in any case, it will all be recycled or reused in some way. “Once it leaves the site, we don’t directly control that process. I don’t know the details yet,” but they will become clear in the fullness of time.

Can we talk? Campus Construction Update loves to hear from you. Please send questions, comments, and inflammatory speculation about construction at Bates College to dhubley@bates.edu, with “Campus Construction” or “Has anyone made the bats-in-the-belfry joke yet?” in the subject line.