One of the destructive torrential rains that have characterized this summer in New England hit Lewiston and Auburn on July 25.

Across the Twin Cities, the evening storm dumped nearly four inches of rain in less than two hours. It flooded streets, buckled pavements, and briefly shut off electricity to hundreds of residents.

In Bates’ neighborhood, the municipal stormwater drainage system was overwhelmed by the runoff. That meant that instead of entering that system as intended, much of the rain falling on Bates stayed at Bates, backing up into buildings and damaging walls, floors, and some equipment — and sparking an impressive cleanup response by the college’s Facilities Services team.

One of those buildings was Chase Hall — nearly ready to reopen after a 14-month renovation that is making this century-old student center a place that’s more welcoming and easier to navigate.

The storm hit one day after all the new furniture for Chase had arrived, three days before the city of Lewiston was scheduled to conduct its formal occupancy inspection, and less than a week before Student Affairs staff were scheduled to move in.

Most of the damage consisted of wet wallboard and carpeting (some of which was installed just hours before the storm). For the most part, the flood was less than an inch deep, but that was enough to necessitate throwing away new carpet and replacing strips of new wallboard adjoining the floor, along with the attached trim strips called “cove base.”

The stormwater affected portions of the lowest floors of Chase: a Residence Life office suite, the ground floor lobby, the Student Affairs offices in the former College Store site, and the bottom level of the new Central Stair.

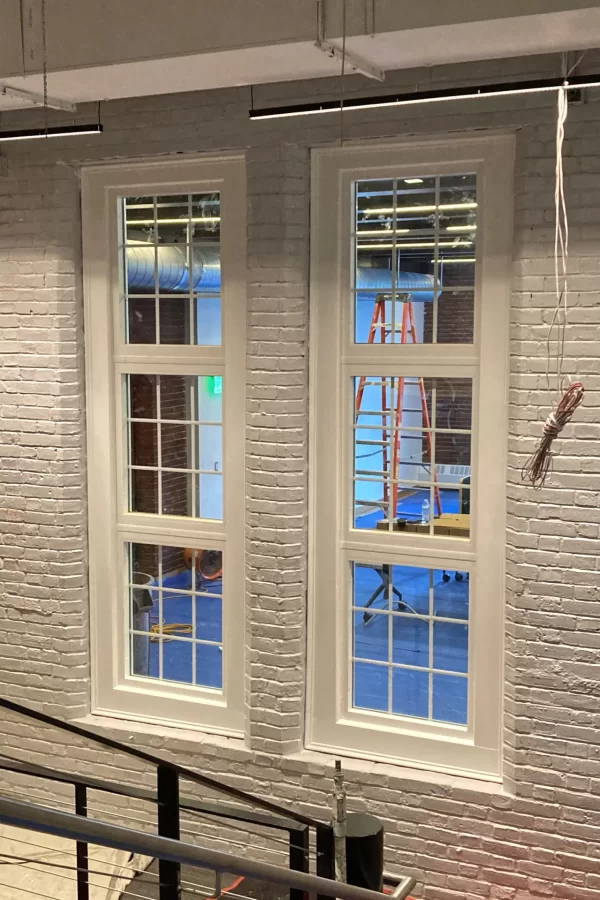

That Central Stair location, in fact, was the scene of the most concentrated water damage. The pit at the base of the new elevator shaft filled up with water, which immersed and thereby ruined both the device that controls elevator speed and the cable that raises and lowers the car.

Still, as Senior Project Manager Paul Farnsworth pointed out during our visit on Aug. 1, the pit sequestered a lot of water that could have caused more widespread trouble elsewhere.

So now, more than two weeks after the deluge, where do things stand with Chase?

The city inspection that precedes the building’s certification for occupancy has been rescheduled for Aug. 25. An opening ceremony for the remodeled Chase is planned for Sept. 7.

And sometime in between, on a date or dates still to be determined, staff for Residence Life, the Center for Purposeful Work, and other Student Affairs functions will move into their new offices.

Just to give you some perspective, Student Affairs’ first heavy lift of the new school year — helping the new Batesies of the Class of 2027 get settled in — commences on Aug. 31. (For a different kind of perspective, the Bobcat Den reopens Aug. 28 after being closed for much too long.)

If the cloud-and-silver-lining metaphor seems tacky in this instance, it’s still true that the storm’s impact on Chase could have been much worse. Much of the building’s new furniture had been placed in storm-affected areas, but waterproof legs and feet resisted any damage. Replacement of the damaged wallboard is underway, and replacement carpet will be laid after the walls are repainted.

And as Farnsworth pointed out, “If this had happened three weeks later, everyone would have moved in and I would have had to move them all out again.”

The storm’s scrambling of the original Chase timetable has even conferred certain advantages. For example, with the move-in delayed, the project team has been able to tackle so-called day-two items — tasks normally left until after the certificate of occupancy has been issued. “We’re able to get a lot of that work done now, rather than having to come back after the building’s occupied,” said Kristi Mynhier, Bates’ project manager for Chase.

In at least one case, in fact, the storm even hastened Chase past a major milestone. As Mynhier explains, it was desirable to get the HVAC system running to help dry out the building. That entailed connecting the system to the campus-wide network of HVAC sensors and controls. So that got done faster than anticipated.

Meanwhile, in areas of Chase that didn’t get wet, the renovation is winding down. With the countertop and other woodwork now in place at the Overnook, the first-floor lobby is about done. The glass walls and doors have been installed around the reception area for the Office of Intercultural Education. And technicians are installing card-access readers in a variety of locations.

As noted, Chase wasn’t the only Bates building harmed by the storm: Carnegie Science, Smith, Hedge, and Kalperis halls were the others. “Merrill Gym and Lindholm House had water that was removed, but no real damage to finishes,” notes Jay Phillips, director of Facility Services operations. (There was water erosion and other damage to the campus grounds, too.)

Phillips adds that some 40 Bates staffers, including custodians and folks in the building trades, were involved in the clean-up and subsequent repairs. A crew from the cleaning and restoration company ServPro also helped out.

When a building is flooded, Phillips explains, “It’s critical to get vent holes drilled and walls opened, drying equipment deployed, and lots of air moving within the first 24 hours, or the risk of mold growth increases.

“Our people responded exceptionally well, and their initial response along with continued action the next day prevented further damage and potential mold growth. I’m always impressed by the incredible work our folks perform and their great professionalism under pressure in these difficult situations.”

Projection room: Immersive Media Studio all but done

Bates’ new Immersive Media Studio, located in a former classroom and computer lab in Coram Library, is close to completion.

Funded by a $500,000 grant from the Sherman Fairchild Foundation, the facility will support instruction in and production of high-tech performances and installations incorporating sound, live action, and projected imagery.

When we visited on Aug. 1, all but a final coat of wall paint, a white “4K” formula that shows projected images to especially good advantage, had been applied. Black floor tiles were placed this week. The ceiling had been coated in matte black paint. With cables newly strung from the control room next door, the ceiling pipe-grid was ready to support the projectors, theatrical lights, and speakers that will cast the digital spells.

Still in their boxes, those gizmos and others were stockpiled in the control room. Technicians from the West Coast firm DBPC had spent the back half of July in there installing computers and controllers, with plans to return and finish up this month, in time for the start of classes.

Tin-knockers get ducts in a row in Hathorn Hall attic

With installation beginning the last week of July, the new retractable stairs that provide access to Hathorn Hall’s attic are in place. Getting to the attic is still a climb, but now a visitor is spared the claustrophobic aspects of the prior arrangement — a steep ladder, jammed into a closet in a faculty office, that topped out in something like the Munsters’ living room but without the laugh track.

Bright new lighting and solid, easily accessed walkways have put an end to the Munstery aspects.

Also in the attic is a new HVAC machine that replaced an obsolete unit, a substitution that in large part was the impetus for the Hathorn attic project. Cote Corp. of Auburn, known for challenging feats of hoisting and rigging, removed the old machine and brought in the new one, which is roughly the size of a chest freezer. Happily, the elevator was large enough to fit each unit, albeit with tolerances as close as an inch or two, says Brian Lanoie, Bates project manager.

The HVAC work also entailed the replacement of a lot of air ducts, work done by the tin-knockers of Nason Mechanical Systems of Auburn. Still to be done on the HVAC front is connecting the new equipment to its power supply and to the campus-wide control network.

More broadly, carpentry contractor M.W. Hoss of Portland needs to restructure the attic floor where a hole was cut for the HVAC equipment (a smaller hole at that location where the new stairs are mounted still remains) and refinish the corresponding third-floor ceiling.

And all that work, taking place through August, will complete this phase of the Hathorn attic project. The next phase, the replacement of the ringer for Hathorn’s bell, has yet to be scheduled.

Garcelon Field turf: ‘Bouncy and cushy‘

With athletic practices scheduled to start before the end of August, the overhaul of a landmark sports facility at Bates is nearly finished.

Home to Bobcat lacrosse, soccer (occasionally), and — with the deepest historical roots — football, Garcelon Field has received a new playing surface this summer. A product called Legion, made by Shaw Sports Turf, the new artificial turf replaces the surface that was installed in 2010 and had reached the limit of its useful life.

An aerial view of Garcelon Field before and after its turf replacement. Use your mouse to grab the slider (or swipe your finger if on a phone or tablet) to reveal more or less of each image. (Branden Rush/Bates College)

Both products comprise a grass-like plastic matrix that’s infilled with a mix of sand and crumb rubber. And both surfaces were installed by R.A.D. Sports of Rockland, Mass.

While the Legion is essentially complete (as is a replacement for the 2010 chain-link fence that had surrounded the field), Garcelon remains closed for another week or two while punch-listing and some tests are being conducted.

The turf came in massive rolls that were spooled out into place across the field by specially equipped tractors. But we were interested to learn from Chris Streifel, Bates project manager for the turf replacement, that a significant proportion of the installation was performed by people using hand tools. Their work included finalizing the placement of the rolls, tweaking their seams, and — perhaps most interesting — setting in all but the biggest markings on the turf.

As a multi-sport field, Garcelon uses different colors for markings pertaining to different games. Most of these graphics can’t be fabricated at the factory and have to be created by hand on site. “So a lot of customized stuff would be done right on the field, and they would cut out pieces and sew in new pieces,” explains Streifel, the college’s director of capital planning and construction.

“Then somebody goes through and checks all that. So they actually spent the last week just going over in fine detail all of those seams.” Note that this is all done on hands and knees.

“And now you can’t even tell” that the work was done by hand. “It all blends together like it was always together from day one.” Streifel adds, “It’s a lot of fine detail and a lot of expertise.”

“It was a very smooth project,” he notes. Because Bates issued its request for bids on the project early, the college was able to get a high slot on R.A.D.’s calendar and avoid the cumulative delays that are almost inevitable over the course of a busy contractor’s summer. “I have nothing but good things to say about the R.A.D. Sports team and Gale Associates, our designer.” Gale is based in Portland.

“The field’s awesome,” Streifel continues. “It’s so fun to step on. It’s so bouncy and cushy, and if I was going to get tackled hard by somebody at this point, that’s where I’d want to have it happen.”

Can we talk? Campus Construction Update loves to hear from you. Please send questions and comments about past, present, future, and past-perfect construction at Bates to dhubley@bates.edu, with “Campus Construction” or “Does this work make you tense?” in the subject line.