Still a constellation of construction hotspots, but with Bates folks scheduled to move back in by the second week of August, newly refurbished Chase Hall had a certain air of anticipation when we visited last week — something along the lines of, “Is it Christmas yet?”

Well, Ralphie, we’re getting there. Parts of the building are all but finished, sitting empty and quiet, such as the first-floor Purposeful Work suite and the second-floor corridor that parallels Campus Avenue. On the second floor, in fact, the conclusive inspection protocol known as punch-listing began last Friday.

In other Chase spaces, though, the 15-month renovation continues full tilt, with tools and supplies fully deployed, various plastics protecting new finishes, extension cords feeding power from temporary electrical boxes, and sprinkler hoses and data cables dangling from open ceiling grids.

In the big picture, as we’ve reported previously, project management firm Consigli Construction expects to hand control of the building back to Bates by the end of July. An interesting focus of attention at the moment is the fire protection system, which includes — in addition to alarms, sprinklers, and illuminated exit signs — controls that, in the event of a fire, switch off the electromagnets that hold certain doors open. The resulting automatic closures of those strategically placed doors can help contain a blaze.

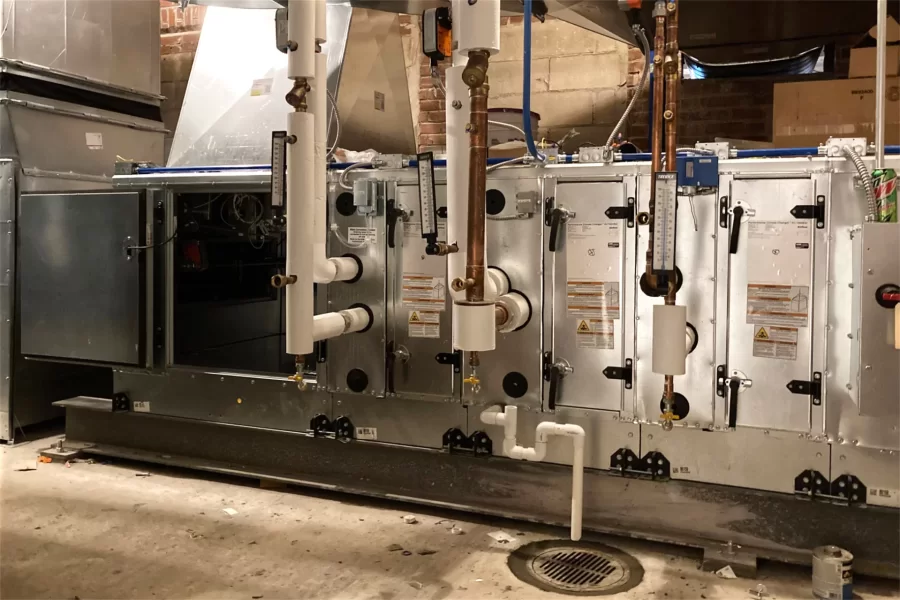

Another system that’s desirable to have in place by the time people move back in, though not directly related to life-safety, comprises local controls for heating, ventilation, and air conditioning, says Bates Project Manager Kristi Mynhier.

Specifically, there are gizmos that tell the system when humans enter a room so that local air flow and temperature will adjust to accommodate their comfort — an amenity that, in the interest of energy conservation, is otherwise quiescent. Those devices are known as occupancy sensors. Professionals call them as “occ sensors,” but that strikes us as occward jargon.

Bond — projecting Flemish bond: When we visited on June 27, bricklayers were piecing in a bold decorative pattern known as projecting Flemish bond on either side of the main Campus Avenue entrance. Over the entrance, the wooden form for a stainless steel awning was in place. Stainless panels on either side lent a sense of how all the steel trim might look when it’s complete.

Around the corner near the Muskie Archives, new facing had been applied to the sides of the former Chase loading dock, which is becoming a sort of patio. A new floor surface, railings, and outdoor furniture are coming soon. Together with gray asphalt pavers that were recently laid at either side, the area will be known as a plaza.

Inside, specifically in Chase Hall Lounge, new “faux beams” have joined the originals. None of these non-load-bearing features hold up the ceiling, but they do prettify it, and the new faux beams will contain light fixtures, so they can lord that sense of practical purpose over the old beams. New hardwood floorboards for the lounge were stacked in the first-floor lobby to acclimate and will be laid near the end of the renovation.

But new oak stair steps are already being installed on the central stair, a sort of three-dimensional crossroads that connects four levels of the building. The job involves two trades, as carpenters fasten the wood in place and rout out a rectangular depression to fit rubber treads, which will then be glued in by flooring installers. Easier to replace than the wooden steps, the inserts will take the wear from all the feet that use the stair (a song lyric in the making!).

Painters are coating the walls throughout the central stair. (And they’ve finished that eye-catching saturated red on the elevator’s wallboard enclosure.)

Painting is in progress in the first-floor lobby, too, including the new Overnook, that slightly elevated seating area along one wall. Before too long, it will sport new steel railings, which are being fabricated in a pattern resembling the famed Bates Manufacturing bedspreads once woven in Lewiston. And that lobby is being cleared of building supplies, aside from the lounge floorboards.

On the upper level of the ground floor — let’s try that again. On what has been called the loading dock level and is now the plaza level — see above — the Residence Life office suite has made big strides since our last visit. Glass doors have been hung at the entrance, most utility terminal fixtures are in place, shiny fan-coil heater-coolers cling to the walls, and fresh paint abounds.

Good griddance

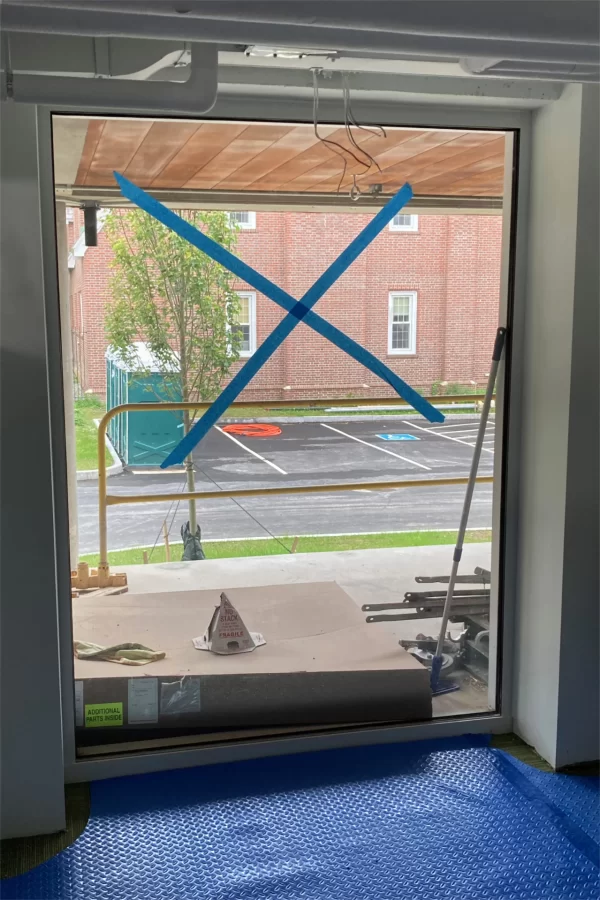

Since our last visit to Coram 110, the future site of Bates’ Immersive Media Studio, its walls have been stripped of features. With the goal of rendering the walls into a smooth white surface suitable for image projection, the space has lost, among other things, interior window frames, chalkboards and projection screens, ventilation grilles, outlets for electricity and data, and a species of wood trim called a chair rail that kept belligerent furniture from roughing up the walls.

While daylight was abundant in the room during our visit, the outdoors won’t be viewable from the former classroom for long: Plywood panels that we saw stacked against the walls will soon block the window openings on the inside, although the exterior frames will remain.

But you know the old saying: When a window closes, a ceiling grid appears, and that’s what has happened in Coram 110. Specifically, it’s a theatrical-grade pipe grid. Composed of black 1.5-inch steel pipe, this sturdy frame will enable studio users “to hang anything anywhere,” said Senior Project Manager Paul Farnsworth, referring to the lights, projectors, speakers, and other gear (disco balls?) that will provide images and sounds for productions in the studio.

The ceiling will be painted black so as not to draw attention away from the immersive art and performance action taking place below. The floor, too, will be black, in the form of quartz tiles.

An adjacent room will be equipped as the studio’s control center, home to the high-powered technology that will drive productions in the studio. In the early project planning, that function was located right in 110 itself. But the erstwhile occupant of the room next door, Michael Hanrahan, Bates’ director for curricular and research computing, volunteered to move his office to Hedge Hall, thereby freeing more space for productions in the studio itself.

The control room, Farnsworth pointed out, houses one of the two massive fireplaces that originally helped to heat Coram, built in 1902. That fireplace has long been hidden behind wall board — but workers drilled through an upper corner of its 120-year-old brick facade to make way for cables that will connect the 21st-century control center to the immersive-studio gizmos on the ceiling grid.

Talk about worlds colliding.

Pad notes

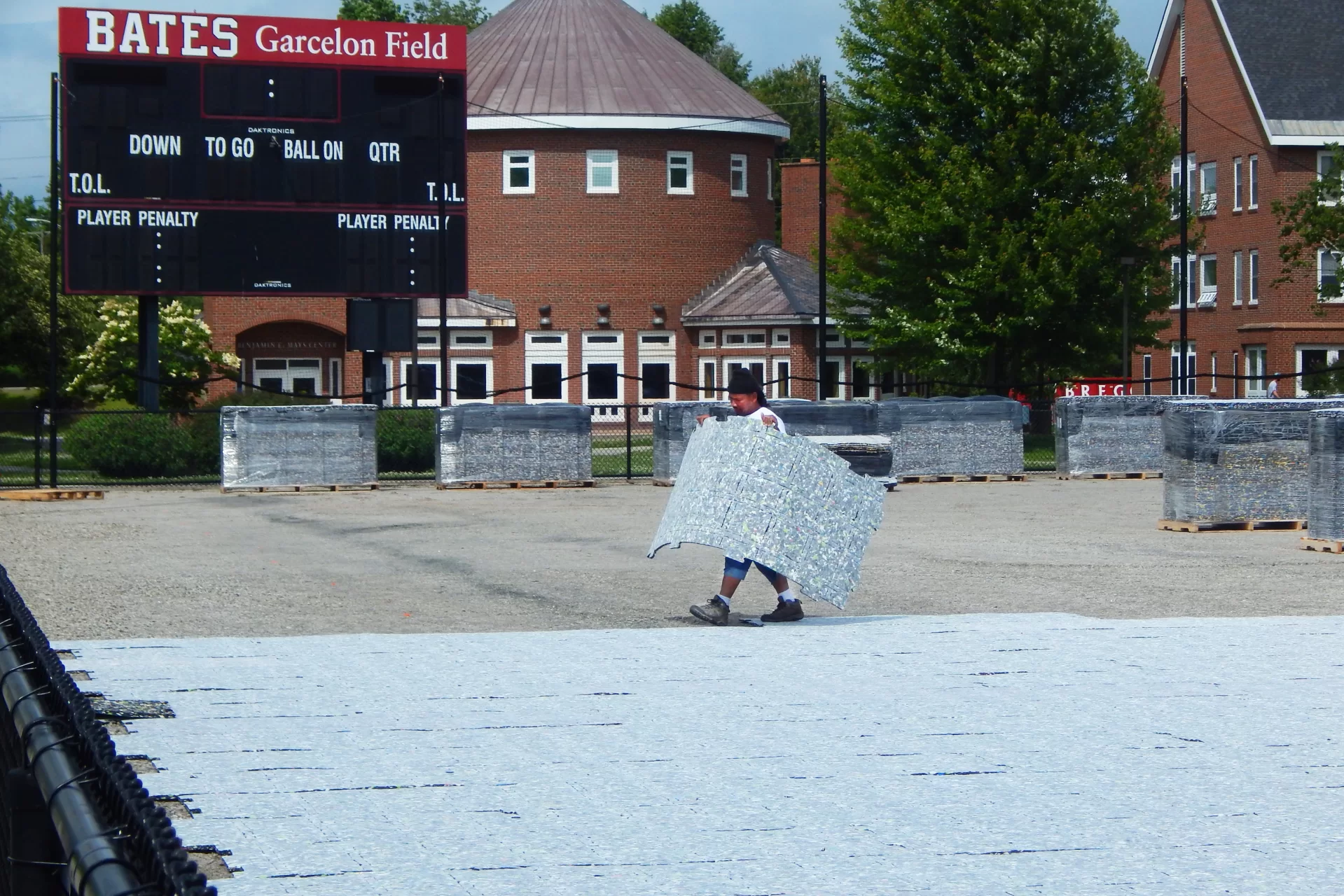

At Garcelon Field, the 13-year-old FieldTurf was removed during the third week of June in preparation for a new playing surface, which is being laid now. When we visited on June 27, the dirt substrate had been graded and a small crew from the project contractor, R.A.D. Sports of Rockland, Mass., was placing a layer of shock-absorbent turf pads that would buffer between the ground and the playing surface itself.

Weighing just a few pounds apiece, the pads are composed of an aggregate of recycled chunks of soft rubber or plastic. It took 4,275 of them to blanket the field, which measures about 100,000 square feet.

They are laid held together by tabs and indents superficially resembling jigsaw puzzle pieces, but in regular shapes and intervals, making the pad layer easy to assemble but not much fun on a rainy day up to camp.

Meanwhile, 40 or so plastic-wrapped rolls of the new playing surface itself, a Shaw Sports Turf product called Legion, were stockpiled around Garcelon along with giant sacks of the sand-and-rubber-crumb infill that will finish the installation. Placement of the Legion started this week, with infill to follow by mid-July.

Ring, but no swing

Over at Hathorn Hall, someone cut a big hole in the third-floor ceiling. All part of the plan, of course, as retractable stairs will eventually be installed in the hole to improve access to the building’s attic and its historic bell.

In addition to the hole in the ceiling (something that some of us get to enjoy with no effort whatsoever!), the project team addressed two other objectives that will make the completion of the overall project easier and safer. One was the installation of several long LED light fixtures, replacing a few dim, widely dispersed lamps. The other was the creation of new walkways.

The hole, by the way, will come in handy during next week when old HVAC machines and ductwork are removed from the attic and a new machine is winched up there for installation. Cote Corp. of Auburn will handle that rigging job. Sometime later, the hole will be smallified to fit the new stairs.

The HVAC upgrade is a major goal of the Hathorn project. A second is to improve access to the bell, whose ringing mechanism will be replaced in hopes of returning the bell to its former prominence. In response to a question from Bruce Lyman ’67, we learned that an electromagnetic striker will supplant the current winch and cable that currently swing the bell. (It hasn’t been determined whether the striker will contact the inside of the bell or the outside.)

A necessary concession to cost and practicality, the proposed striker will mean the bell no longer swings to ring. But a representative of the ringing mechanism provider, Elderhorst Bells Inc. of Palm, Pa., assures us that the striker can be made to emulate the characteristic, romantic “double ring” of a swinging bell before it comes to rest.

Can we talk? Campus Construction Update loves to hear from you. Please send questions and comments about past, present, future, and past-perfect construction at Bates to dhubley@bates.edu, with “Campus Construction” or “You used that Flemish bond joke already before!” in the subject line.