Others may be eagerly anticipating beach trips, camping, cookouts, etc., but for Campus Construction Update summer means one thing and one thing only: facility projects at Bates.

As always, this year’s summer initiatives comprise a nice variety. Academic projects include new kilns for the Olin Arts Center and the creation of specialized labs for new faculty (including facilities for sleep research and for analyzing interactions between sunlight and atmospheric pollutants).

As it has been all year, though, the biggest construction news might be the conversion of the former Sisters of Charity convent at 96 Campus Avenue into the college’s newest student residence. Scheduled to open in time for the forthcoming academic year, that project will stay on our radar all summer long.

In this edition of CCU we’ll also describe a quick project at Lindholm House, a campus landmark and home of the Admission office. And we’ll tell you about yet another upgrade at the Russell Street Field, a facility that has gotten quite a lot of love in recent years.

Get out: Last month we explained how the work at 96 Campus Avenue has expanded to the building’s exterior and surroundings. That trend has intensified.

On May 10, the riggers of Cote Corp. brought a crane over from Auburn to hoist two new air handlers, specifically known as energy-recovery ventilators, to the roof. (They also wrangled into the basement two gas-fired boilers that will provide hot water for things like showers, ramen noodles and Swiss Miss hot chocolate, and laundry.)

A couple weeks later, we visited just in time to witness the start of paving as the site-work experts of Lewiston firm St. Laurent & Son laid a binder coat of asphalt on the reconfigured parking lot.

Thinking about chains of causality can bend your mind, as we have reason to know. That paving job is a good example. From now until the second and final coat of asphalt is laid, late in the project, tradespeople on the job at 96 Campus Avenue can park in the newly paved lot instead of along the Bates service road adjacent to it.

That will clear the way for the construction of a new sidewalk along the service road that will link No. 96 to campus, via the walkway that passes Merrill Gym and the Bobcat statue. A gravel roadbed for the sidewalk’s asphalt has already been prepared.

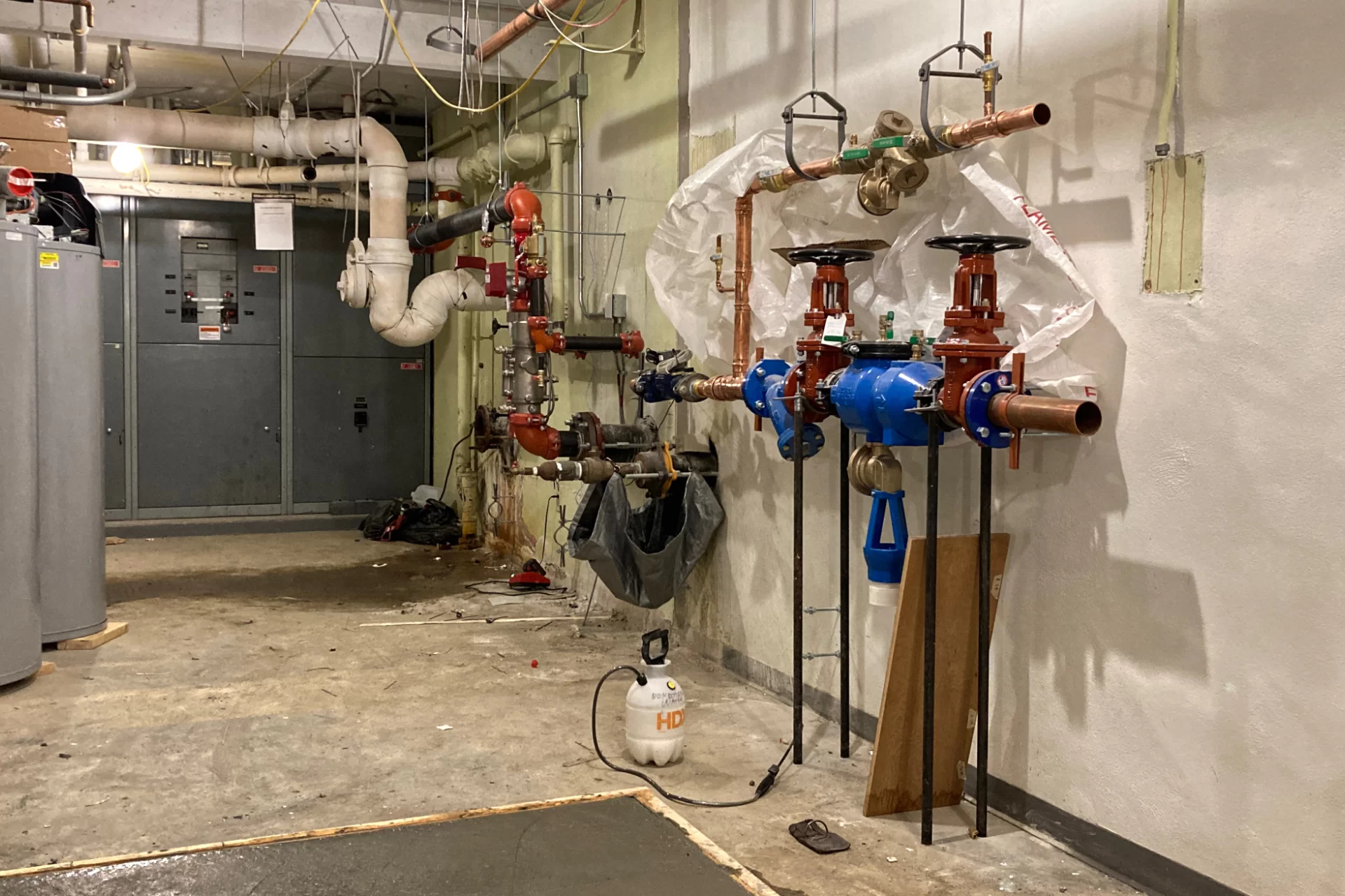

In early May, prior to paving, new underground connections for local utilities were run through the parking lot. The business of tying those utilities — fresh water, gas for the water heaters, stormwater and sanitary discharge — into building systems has been going on ever since.

Bates Project Manager Brian Lanoie took us to the basement to see the massive pipe-and-valve assemblages where the incoming and outbound water connections have been made but not yet opened. The new gas line was missing, waiting for Unitil to install its meter outside the foundation. Lanoie added, “There are still some wires that need to be pulled for power, but the (electrical) infrastructure is all in place.”

We spotted the new water heaters and, nearby, a concrete pad just poured for their permanent location. Lanoie also pointed out that the mechanical area in the basement had been reconfigured since our last visit. A wall was removed and will be rebuilt so as to enlarge the mechanical space and shrink an adjacent storage room.

With the building’s electrical lockers lining an entire end wall, the change in floor plan was necessitated by the building code, which specifies a distance between a water intake and the electrical service greater than what was called for when 96 Campus Avenue was built, nearly a half-century ago.

Ultimately, though the mechanical area is the focus of basement work, the whole level will be cleaned and repainted, and some damaged wallboard replaced, before the renovation is done.

Progress on the first floor since our last visit was conspicuous. Notably, expanses of wallboard have been hung, largely at the north end of the building (farthest from Campus Avenue), where the residence director’s apartment and the building-wide student lounge will be located. It’s amazing the difference that walls make to how we perceive a given amount of space.

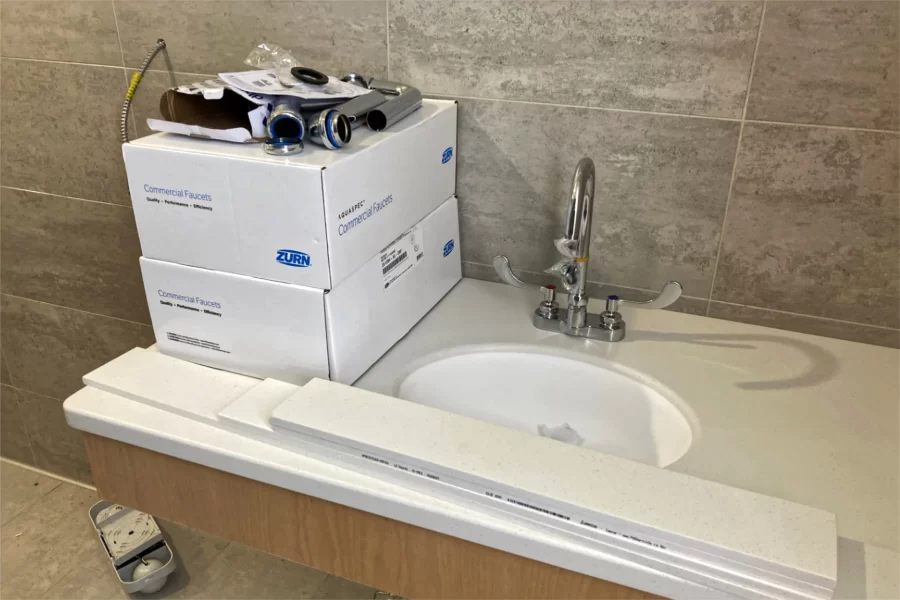

Where MEP on the first floor is more about bringing utility feeds to new destinations and then roughing them into walls, upstairs the focus is more on terminal installations — lights and light switches, sinks and toilets, etc. Plenty of those fittings are in place on the third and uppermost level, and they’re appearing one floor down, too.

Most third-floor walls have been painted with primer, many doorframes are hung, and millwork, such as wooden shelves, is being added to student rooms. New flooring is going down — a simulated wood-grain product in bedrooms and hallways, tiles in the restrooms.

As noted, these same processes are happening on the second floor, too, just a little bit behind the third. The big news on the second floor is the dramatic change to what was originally built as the convent’s chapel — now divided into student rooms with remarkably high ceilings.

Overall, the transformation of 96 Campus Avenue is “still tracking on schedule and on budget,” Lanoie said. “We’ve been blessed in a few different ways with the project, and some of the changes that have occurred all went the right way.”

Trenching afoot: The home of the Admission staff, Lindholm House underwent improvements to its foundation in May. Prompted by persistent water leakage into the basement, the project entailed excavation around the building, creation of new drainage infrastructure, and exterior application of a waterproofing membrane. Amos Development of Greene was the contractor.

In the process, Lindholm got a new set of front steps through the efforts of Randall Swan, a local builder who has done work for Bates since the early 2000s. He fashioned the steps from Trex and AZEK, wood substitutes made from recycled materials. The front walk was replaced this week and new plantings, selected with guidance from Admission staff, will appear before too long.

Grassroots campaign: It’s turf’s up! for Russell Street Field, the venue for Bobcat track and field and one of two home pitches used by the varsity soccer teams.

In a makeover expected to begin any day now, the facility will receive a new scoreboard, energy-saving field lights, and an artificial playing surface to replace the living grass inside the track.

When complete, the field will join Garcelon Field as a multipurpose turf field available to students for more hours each day, more days each year, and for more sporting and recreational activities.

Field turf manufacturer FieldTurf (talk about no-nonsense marketing!), whose products have been used at Bates previously, is supplying the new surface. Called CORE, the product is described by the manufacturer as the first-ever multi-layer dual-polymer fiber. (Apparently they’ve overlooked some leisure suits we got at Jordan Marsh in the 1970s.)

The turf will replace all the grass inside the track, about two acres’ worth. Typical of such surfaces, it’s composed of simulated grass blades infilled with layers of sand and two grades of rubber crumbs. This infill provides cushioning and stability. The crumbs are made by shattering deep-frozen vehicle tires.

The grass is only 5 years old, but between heavy use and the summertime thrill ride of alternating droughts and deluges, upkeep has been challenging. Moreover, the new surface will make the field not only more durable, but more versatile. For example, its markings can be switched out to accommodate other sports, such as rugby.

A major Maine contractor is handling the project: Shaw Brothers Construction of Gorham. “They’ve done quite a few fields,” says Paul Farnsworth, Bates project manager for Russell Street Field.

“They’ll dig out the existing grass and underlayers, and then build it up with select gradations of fill.” The overall carpet of FieldTurf will be attached to pressure-treated wood laid underneath, as well as to a concrete band that will be carved from a retaining wall around the inner circumference of the track.

The track surface, by the way, was replaced in 2022. “We’re taking extraordinary measures to protect the track” from damage caused by heavy-equipment crossings, says Farnsworth, describing a sort of Dagwood sandwich of steel plates, landscape fabric, sand, and articulated wooden mats.

This all promises to reward the observation of Shaw Bros.’ progress at the field. But Farnsworth says that passers-by will also notice the big holes being dug around the site as footings are placed for the new field lights. These tall appliances will be manufactured by Musco Sports Lighting, which in 2010 also supplied the lights for the Garcelon Field makeover. But the Russell Street units will be electron-sipping LED lights.

The new scoreboard, meanwhile, will be capable of displaying not only scores but pre-programmed images and text, such as player portraits and their stats. Finally, Farnsworth notes, the javelin-throwing runway will be moved to a location behind the softball field.

Can we talk? Campus Construction Update welcomes your questions, comments, and reminiscences about construction at Bates. Putting “Campus Construction” or “Do you wear the chains of causality you forged in life?” in the subject line, please contact Doug Hubley at dhubley@bates.edu.

Doug Hubley is a writer and musician living in Portland, Maine.