In case you believe that the primary role of a Facility Services project manager at Bates is to escort Campus Construction Update through work zones, we are here to disabuse you of that notion.

In fact, even after 18 years as CCU, we can still be surprised by the variety of tasks to which people like Paul Farnsworth, senior project manager, apply their creativity, people skills, and attention to detail.

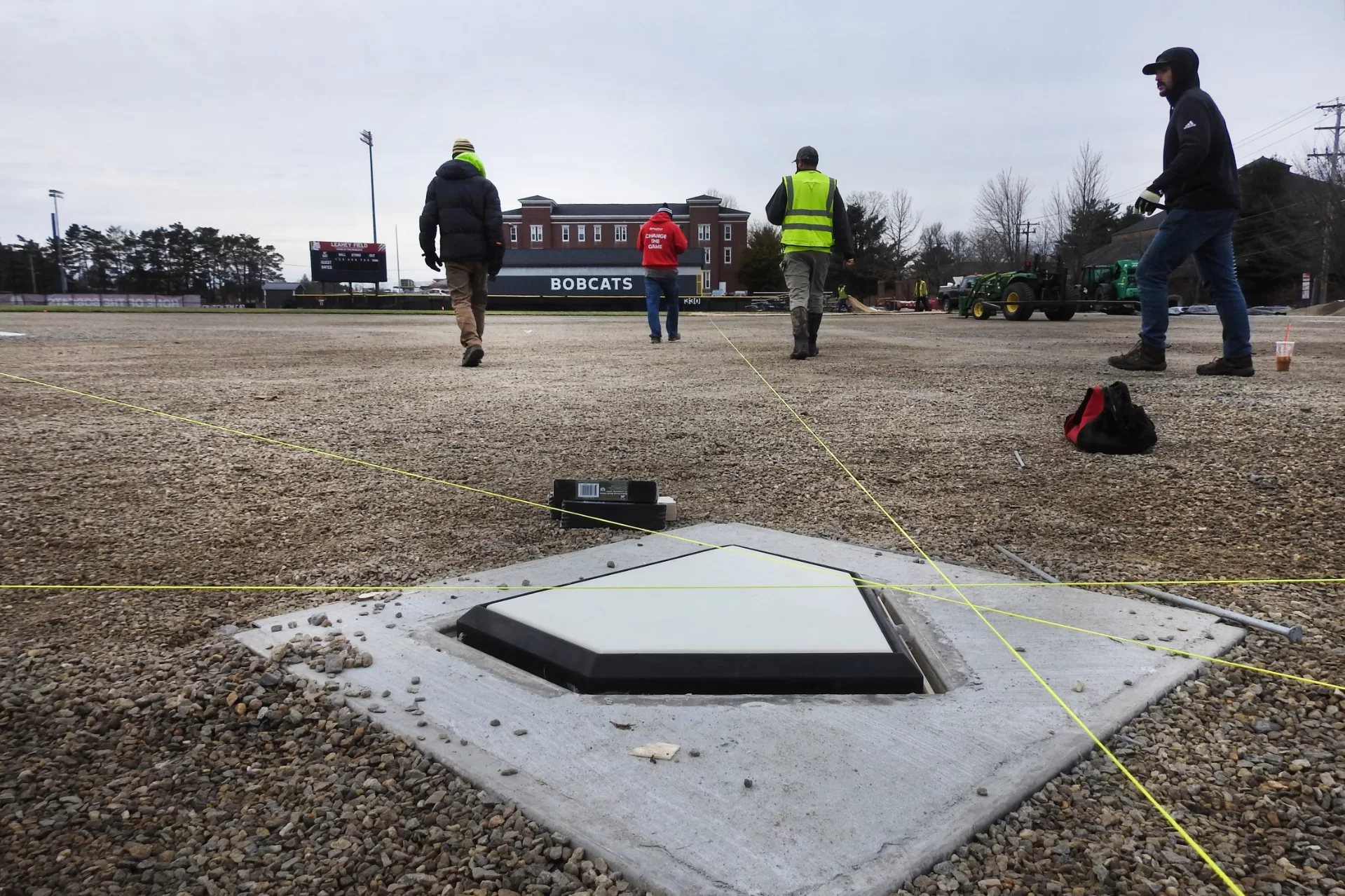

Example: When the installation of artificial turf on Bates’ baseball field is complete, by mid-November or so, that process will actually render Leahey Field a hybrid. The new artificial turf will cover the infield and a margin just beyond the baselines (to extend benefits of the turf to the baseline action), but natural grass will remain the playing surface on most of the outfield.

This mix of surfaces is new to Bates.

Moreover, the boundary between the real and the manufactured sod includes a buried concrete curb and gasket that help to anchor the new FieldTurf. That raised a question: Might that curb affect how a ball that’s in play bounces or rolls?

Answering that fell to Farnsworth in collaboration with, among others, Facility Services colleagues (representing the Grounds and the Capital Planning and Construction teams) and folks from Athletics.

The research included visits to Bridgton (Maine) Academy, which has had the two-turfs arrangement for a few years. The Bates visitors even “rolled balls across the transition at Bridgton and found that it didn’t seem to make a difference,” Farnsworth says.

In addition, Farnsworth and Head Baseball Coach Jon Martin had a phone conversation with the coach at Chapman College, “which has this setup as well,” he adds.

That’s a fair amount of research to get a simple — but important — answer.

If the FieldTurf brand sounds familiar, that’s because the manufacturer has already topped one playing field at Bates this year: the soccer pitch on Russell Street. At Leahey, the turf product comes from the manufacturer’s baseball-specific DoublePlay line. Under the direction of construction management firm Shaw Brothers, based in Gorham, Maine, outdoor work on the project began Oct. 2.

The new infield surface will relieve problems inherent to the twin challenges of growing grass on soil rich in marine clay and maintaining the dirt portions of the infield. Those include poor drainage, vulnerability to grass damage, and a “feel” underfoot that varies with soil moisture. For instance, living grass must be covered with something waterproof before a rainfall or it will be too wet for play. Artificial turf drains immediately, so there’s no need to cover it.

Spring snowfalls pose similar problems: A field can be plowed once, but because snow acts as an insulator, a subsequent snowfall onto the bare grass is more likely to melt and make the ground too soft for a game. (And if you’re wondering why the outfield was mostly left natural, it’s because there’s much less traffic there during a game than the infield, so poor drainage is less of an impediment.)

Placement of the DoublePlay turf began this week. The month prior went into site preparation. Going down a foot or so, “they removed the topsoil and leveled off” the subsoil, Farnsworth says, and placed layers of crushed stone to promote drainage.

Toward that same end, new drainage infrastructure was implanted. That comprises so-called panel drains that conduct seepage to 12-inch collector pipes under the first and third baselines. Those pipes route the water to a concrete cistern and thence to the college runoff system that drains into Lake Andrews.

Based on the principle that what goes around comes around, not only was Leahey’s drainage system replaced but the irrigation system too. “A lot of the old irrigation was for the infield, which we don’t need anymore, so we had to reroute the feed to it. So there’s pretty much a whole new system in to handle the outfield,” Farnsworth says.

In addition to the curb created around the perimeter to secure the FieldTurf, concrete work included a pitching mound that, because of the wear it receives from the antics of pitchers’ feet, will be covered with a replaceable topper. That layer will be held in place with a hook-and-loop fastening (e.g., Velcro).

Similar replaceable mats will cover the two batting boxes, as well.

Along the first- and third-base sidelines is more FieldTurf, for newly redesigned home and visitors’ bullpens. “What surprises a lot of people,” Farnsworth notes, “is that you’re required to give the bullpens the same surface as the field.” That enables pitchers to warm up on the same material that they’ll actually be standing on to throw.

“They’re large structures. They have to face the same direction you’re pitching in, toward the northwest. Obviously you don’t want to warm up facing the sun, when that’s not where you’re going to be pitching.”

Other chores include replacing grass along the perimeter of the infield, where excavation for the concrete curb was done. “We brought in sod the third week of October so we’d have something to play on come spring. If we had relied on loam and seed, it wouldn’t have grown enough by the time we start playing.”

Finally, in order to keep foul balls and other ballistic curiosities from wreaking havoc among the cars parked along Central Avenue, Leahey will also get a new backstop and netting system — but not till after the 2025 baseball season has ended. The current net will serve till then.

“We didn’t think we’d make our schedule with so much additional work that has to be done before this turf went down,” Farnsworth explains, “so we elected to postpone the net until after the baseball season. We extended the new turf to the old backstop to get us through.”

“If we don’t get it done before snow flies, that’s how it’s going to be when the season starts.” The new net will be 40 feet high, secured by foundations 16 feet deep, and located about 20 feet closer to home plate than the current setup. New to the arrangement will be a 3-foot high masonry wall, brick-faced and padded on the field side.

And speaking of the Russell Street Field renovation, a final touch was applied there this week. Scoreboard Specialties of Mansfield, Mass., came north to install a new board at the soccer field. Featuring snazzy LED video displays, the unit was fabricated by Daktronics of Brookings, S.D. Funded by donors, the scoreboard is in memory of the late Bates track and cross country coach Al Fereshetian, who died in June 2024.

Can we talk? Campus Construction Update loves to hear from you. Please send questions and comments about construction at Bates College to dhubley@bates.edu, with “Campus Construction” or “Say, who was that shadowy individual, anyway?” in the subject line.